In any workplace environment, ensuring the safety and well-being of employees is paramount. An effective electrical safety audit serves as a proactive measure to identify potential hazards, assess compliance with safety regulations, and mitigate risks associated with electrical systems. By conducting regular audits, businesses can create a safer working environment, prevent accidents, and promote a culture of safety. In this article, we’ll explore the key components of an effective electrical safety audit checklist, highlighting the importance of proactive risk management and adherence to industry best practices. You can reach out to Texas-Solutech for all your electrical safety audit needs, because we are experts in the field.

Understanding the Importance of an Effective Electrical Safety Audit

An effective electrical safety audit is more than just a regulatory requirement; it is a crucial aspect of maintaining a safe and secure workplace environment. By systematically assessing electrical systems, equipment, and practices, businesses can identify potential hazards, rectify deficiencies, and minimize the risk of electrical accidents and injuries. An effective electrical safety audit serves as a proactive measure to protect employees, safeguard assets, and uphold regulatory compliance.

Key Components of an Effective Electrical Safety Audit Checklist

- Documentation Review:

- A complete electrical safety audit begins with a comprehensive review of documentation, including electrical schematics, equipment manuals, and maintenance records.

- Reviewing documentation helps auditors gain insights into the history and condition of electrical systems, identify maintenance requirements, and ensure compliance with regulatory standards.

- Visual Inspection of Electrical Systems and Equipment:

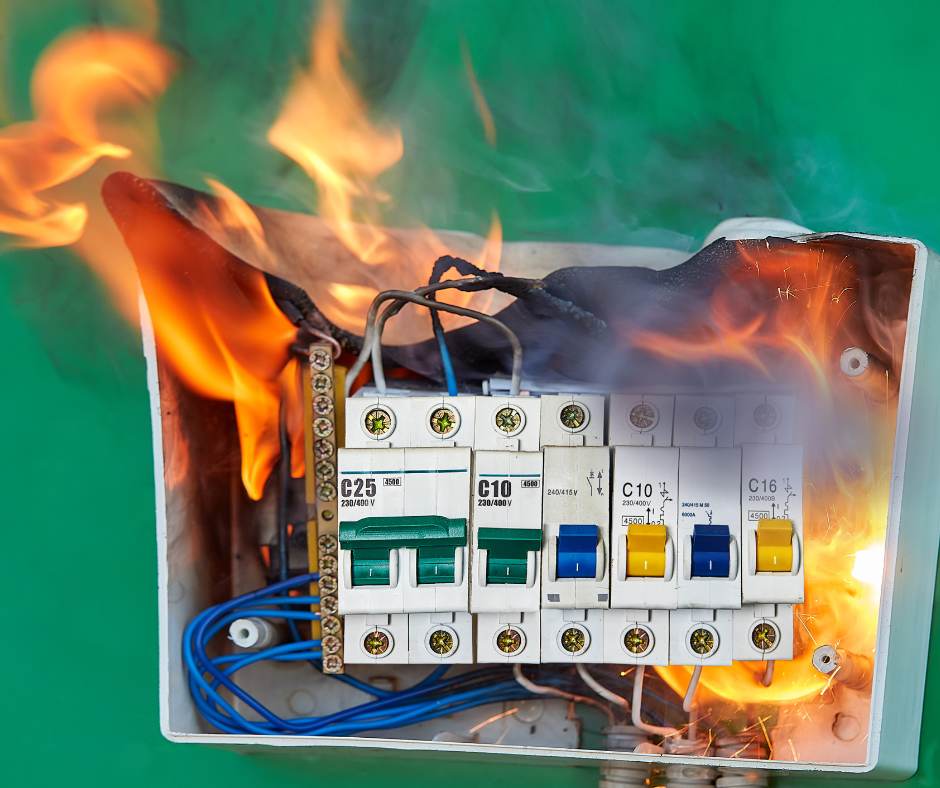

- Visual inspection is a critical component of an effective electrical safety audit, allowing auditors to assess the condition of electrical systems and equipment.

- Auditors should inspect wiring, circuit breakers, outlets, and other components for signs of damage, wear, or corrosion that could pose safety risks.

- Visual inspection also includes checking for proper labeling, clearances, and accessibility of electrical equipment to ensure compliance with safety standards.

- Assessment of Electrical Load and Capacity:

- Auditors should assess the electrical load and capacity of circuits and equipment to ensure they are not overloaded, which can lead to overheating and potential fire hazards.

- By verifying load calculations and assessing voltage, amperage, and power factor, auditors can identify areas where adjustments or upgrades may be necessary to maintain safety and efficiency.

- Testing of Grounding and Bonding Systems:

- Grounding and bonding systems play a crucial role in protecting against electrical shocks and ensuring the safe operation of electrical equipment.

- Auditors should conduct tests to verify the integrity of grounding and bonding systems, including continuity testing, ground resistance measurements, and inspection of connections and electrodes.

- Evaluation of Emergency Response and Shutdown Procedures:

- An effective electrical safety audit includes an evaluation of emergency response and shutdown procedures to ensure that employees are adequately trained and prepared to respond to electrical emergencies.

- Auditors should review evacuation plans, emergency contact information, and procedures for isolating and de-energizing electrical systems in the event of an emergency.

- Review of Training and Awareness Programs:

- Training and awareness programs are essential components of a comprehensive electrical safety program.

- Auditors should review training records, documentation of safety meetings, and employee feedback to assess the effectiveness of training programs and identify areas for improvement.

- Documentation of Findings and Recommendations:

- Following the audit, auditors should document their findings, including any deficiencies or areas of concern identified during the inspection.

- Recommendations for corrective actions and improvements should be clearly documented, along with proposed timelines and responsibilities for implementation.

- Follow-Up and Monitoring:

- An effective electrical safety audit does not end with the inspection; it requires ongoing follow-up and monitoring to ensure that corrective actions are implemented and maintained.

- Auditors should establish protocols for follow-up inspections, monitoring of corrective actions, and periodic reassessment of electrical systems to maintain compliance and effectiveness.

Conclusion

In conclusion, an effective electrical safety audit is a vital component of maintaining a safe and secure workplace environment. By conducting regular audits and adhering to industry best practices, businesses can identify potential hazards, mitigate risks, and promote a culture of safety among employees. The key components outlined in this article provide a framework for conducting comprehensive electrical safety audits and ensuring the ongoing protection of employees and assets.